What can I use for concrete resurfacing? 5 common concrete coating types

After finding yourself staring at the window, daydreaming at work, you start to think about your home. While it is yours, you start to yearn to make some custom renovations.

Should you knock out a wall and expand the guest room? Make space for an outdoor kitchen? Get a new jacuzzi for your bathroom?

These all seem like they would be great customizations to really make your home yours, however, much more costly than you’re looking to invest in right now.

Later, you see a Facebook post of one of your neighbors who just got their garage floor redone with a coating that almost looks like granite.

That’s it! This is the type of project you are looking for. Now dozens of questions race through your mind.

What is concrete resurfacing? Are there different kinds? Which one is the best? Which one should I choose? We’re here to help.

Video "What CanYou Use for Concrete Resurfacing?" down below

Southwest Exteriors has been an exterior remodeling contractor in San Antonio since 1989. We’ve become experts in concrete coatings and offer Penntek polyurea coatings and install them on garage floors, pools decks, patios, and sidewalks every week.

We offer polyurea coatings because they’re the most durable for a concrete surface. However, we know that it might not be the coating type that everyone is looking for.

This article will detail the five most common types of concrete coatings and discuss what they’re made of, their benefits, and the designability of each of them.

After reading, you’ll know the basics of the most common types of concrete coatings and can determine which kind is right for you.

1. Polyurea coating

What is polyurea coating?

Polyurea coatings are one of the most popular types of concrete coatings. Polyurea is an elastomer made by bonding a synthetic resin with an isocyanate material through step-growth polymerization.

What the heck does that even mean?

Basically, polyurea is a combination of a polymer and isocyanate, a flexible compound used in fibers and foams and is also used to strengthen concrete, steel, and fiberglass. This creates a durable and flexible mixture for a concrete coating.

Polyurea coatings are typically paired with a polyaspartic topcoat or mixture of the two. Polyaspartic is another type of polymer and adds to the quick-dry time of polyurea coatings.

What are the benefits of a polyurea coating?

-

Extremely durable and flexible

-

Withstands changing temperatures

-

High impact resistance

-

Resistant to fading

-

Fast dry time

-

Long lasting

Because of their makeup, polyurea concrete coatings are one of the most durable coatings available. Their flexibility is beneficial to withstand varying temperatures without cracking under pressure (pardon the cheesy pun).

Their durability also allows them to stand up against large weights and impact, making them a great solution for a garage-turned-at-home-gym.

Polyurea coatings are also resistant to fading from excessive UV exposure and have fast cure times - as fast as 24 hours. They typically last 15 plus years.

What are the drawbacks of a polyurea coating?

-

Fast cure time can make application difficult

-

More expensive type of coating

While the cure time of a polyurea coating is considered a benefit, it can also be a drawback when it comes to installation. If the polyurea coating is not applied in the proper amount of time, the composition of the coating mixture can start to harden and change the outcome of installation if the contractor is not aware.

Polyurea coatings are also one of the pricier coatings, so if you are looking for the least expensive option, it might not be for you.

What kind of designs do polyurea coatings offer?

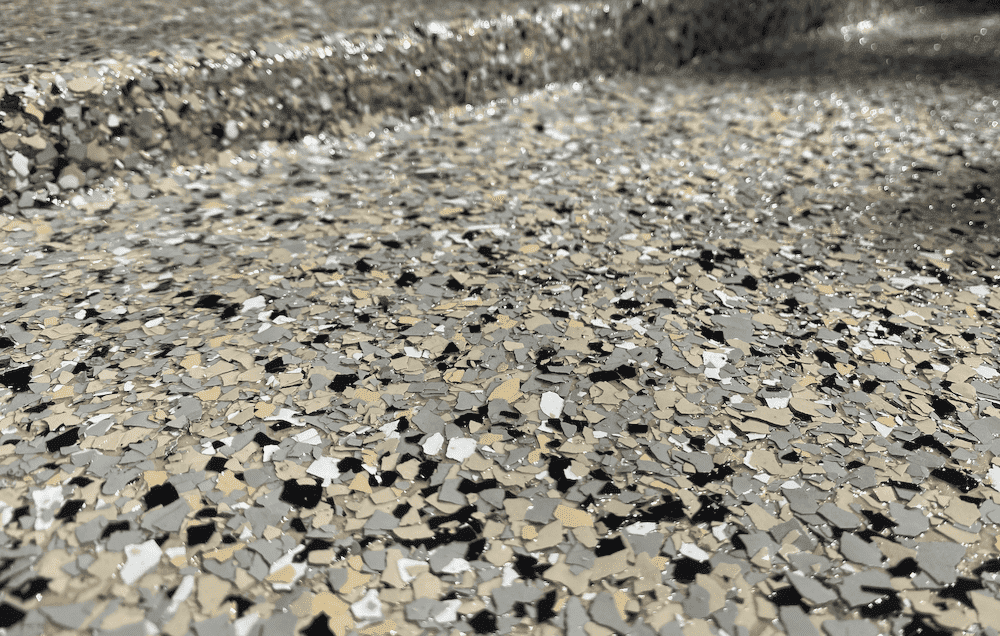

Polyurea coatings can be applied as solid colors with a shine finish. More popularly, polyurea coatings can be combined with vinyl chip colors to create a quartz-looking finish.

Depending on your contractor, these vinyl chip colors can be customized to create a blend of whatever colors you like. This makes polyurea coatings a great option if you are looking for a unique, one-of-a-kind coating.

2. Epoxy coating

What is an epoxy coating?

Epoxy is the second most popular type of concrete coating and possibly the most well-known. Epoxy is a type of polymer.

A polymer is a material made up of large molecules strung together over and over again. The structure of a polymer makes it elastic and tough, which is why it is popularly used in construction.

Other examples of polymers are wool, DNA, fingernails, and hair.

An epoxy mixture used for concrete coatings consists of a resin and a hardener. The two are mixed and spread evenly over the surface to bond with the concrete.

You can look at an epoxy coating similar to paint. It sits on the surface of the concrete and doesn’t bond itself down to the roots.

What are the benefits of an epoxy coating?

-

Durable

-

Resistant to tire marks, scratches, staining, and impact

Epoxy is known for its durability. For a garage floor coating it can withstand tire marks, chemicals, stains, scratching, and general impact.

This makes epoxy a sturdy competitor compared to polyurea.

Epoxy coatings typically last 3-5 years before you start to see general wear and tear and possible damage.

What are the drawbacks of epoxy coatings?

-

Can warp under high heat and changing temperature

-

Fades under UV rays

However, if you are constantly pulling into your garage after a long drive, the heat from your tires is going to wear down on the epoxy within a few years. UV heat will also wear and cause yellowing in the epoxy in outdoor areas.

What kind of designs do epoxy coatings offer?

Because epoxy is similar to polyurea, the design capabilities are also similar. Epoxy is more popularly used for solid colored coatings but is also becoming available with colored vinyl chips.

Some contractors offer metallic epoxy coatings that are made to give your surface a marble-type look.

Photo credit: Decorative Concrete Kingdom. This image was not altered in any way.

3. Polyurethane coating

What is a polyurethane coating?

Polyurethane is similar to polyurea and is also a polymer, like epoxy. Polyurethane coatings can be either water-based or oil-based. It is made by the joining of carbamates, which is an organic compound, and creates more of a plastic material.

Water-based coatings have a quick dry time and are thinner than oil-based coatings. Oil-based polyurethane is more durable than water-based and can withstand heat better than water-based.

Polyurethane coatings are also popular for wood surfaces and are made to act as a sealant to protect the surface and integrity of the material.

What are the benefits of a polyurethane coating?

-

Flexible

-

Resistant to scratching

-

High-temperature resistant

Polyurethane coatings are more flexible like polyurea, making them a viable solution for garage floors to withstand the weight of cars, storage cabinets, and exercise equipment. This also makes them highly resistant to scratches and abrasions.

These types of coatings are also highly temperature resistant, meaning they will withstand heat from the sun, making them a great option for outdoor areas like driveways and sidewalks.

What are the drawbacks of polyurethane coatings?

-

Can bubble in moist climates, causing peeling

-

Do not bond well with concrete

-

High VOCs

Although they are offered for concrete coatings, polyurethane coatings do not bond well with concrete. They are also known not to perform well in areas with high humidity or when exposed to moisture.

Small bubbles can form underneath the coating when exposed to moisture or applied over moisture. This is why it is so important to take the necessary steps to ensure the concrete has a low enough moisture content before applying a coating.

Polyurethane coatings are also known for their high VOCs, or volatile organic compounds. This creates a strong smell from the coating and can linger longer than preferred.

What kind of design do polyurethane coatings offer?

Polyurethane is commonly mistaken for epoxy coatings with a shiny solid finish. They can be solid-colored or a clear topcoat, so if you’re looking just to add a shiny coating to your concrete flooring, polyurethane might be the right choice for you.

Photo credit: Prime Coat Coating Systems

4. Acrylic coating

What is an acrylic coating?

Acrylic is a compound made of monomers to form a polymer. Monomers are mostly organic molecules that, when combined, string together to form a polymer.

In this simple compound, acrylic is created. You may know acrylics most commonly as plexiglass, so acrylic is essentially a plastic.

Acrylic coatings are mainly used for topcoats to provide a shine over the surface or epoxy coating.

What are the benefits of an acrylic coating?

-

Provides a shiny topcoat

-

Fast drying

-

Scratch resistant

Acrylic coatings are best used for topcoats on top of a thicker base. When coated, they provide a shiny and durable surface to freshen up an old surface.

Though they are not the most durable option available, acrylic coatings are known to be scratch resistant and fast-drying, making them a quick and easy option if you’re looking for a fast solution.

What are the drawbacks of an acrylic coating?

-

Can chip under high impact

-

Quick dry time makes it difficult to apply properly

Because acrylic is mainly used as a top coat, it is not the best option as a main concrete coating. While acrylic coatings can be flexible when combined with a strong base, they can be susceptible to chipping when met with high impact.

Its quick-dry time can also make it difficult to apply fast enough without compromising the composition of the material. This can create an overall uneven application.

What kind of designs do acrylic coatings offer?

Acrylic is most commonly used as a clear topcoat, giving you a shiny finish to your concrete surface.

Acrylic paints are also another option for a more colorful coating, which we will dive more into below.

Photo credit: All Garage Floors

5. Paint coatings

What are paint coatings?

The final type of coating is a simple paint coating. While paints are used for many things, they can also be used for concrete coatings, though not incredibly popular.

Paint is made up mostly of resins, solvents, and pigment for color. The resin and solvent combination helps the paint to apply easier and dry faster.

It is mostly used as a sealant for concrete and is a simple solution if you’re looking for a quick project.

What are the benefits of a paint coating?

-

Quick dry time

-

Low VOCs

-

Extra sealant to concrete

Painting over your concrete is a great option if you want to spruce up an area in a simple way. Most paints have a quick dry-time and low VOCs, so their fumes are not harmful to you and won’t linger too long.

While paints are not the most durable option for a concrete coating, they can provide an extra level of protection over the surface as an added sealant.

What are the drawbacks of a paint coating?

-

Not very durable

-

Chips under impact

-

Color can fade quickly

Paint can add some protection to concrete, but it is not the most durable option out there. High-traffic areas can be susceptible to easy wear and tear, and paint can chip upon high impact.

Most paints tend to have low UV resistance, meaning in outdoor areas, the color can fade quickly.

What design options do paint coatings offer?

You can create paint in any custom color you like. This means that for a paint coating, your options are endless when it comes to choosing a color.

Paint coatings are also a great material to use to create detailed patterns or a work of art and are easier to apply in intricate ways than other coatings.

Photo credit: Bob Vila

Which type of concrete coating is right for me?

With many options out there, it can be overwhelming and confusing to choose the right one for you. When looking for a concrete coating product, you must consider your goals for your project.

Are you looking for something that is going to last a lifetime in your home? Then polyurea might be the right option for you.

Are you wanting to add a custom DIY design to your garage floor without breaking the bank? Then maybe a paint application might be the way to go.

You want to consider how long you want the coating to last, what durable qualities you want it to have, and what you want it to look like.

Outline what you want out of your concrete resurfacing project to help find the right material for you, like longevity, durability, aesthetics, and safety. Then, you can filter the right concrete coating material types that fit your criteria.

At Southwest Exteriors, we offer polyurea coatings from Penntek with a polyaspartic topcoat because of their superior durability, longevity, and overall quality. If you’re looking for a one-day, high-quality polyurea concrete coating with custom design and color options, then we might be the right contractor for you.

After learning about different concrete coating types and outlining what your goals for your concrete coating are, you might be wondering how much a concrete coating project costs.

It’s important to understand what all adds to the total cost of a concrete coating project so you can have realistic expectations for your project.

This article and video will outline the top three factors that influence the cost of a garage floor coating so you know what to think about and consider when budgeting for your project.