If you’re shopping for a window or a glass door, you may have heard the term, Insulated Glass Unit, or IGU.

What you may not have heard is that the IGU is the most important part of a window or glass door. In fact, the right IGU can be the difference between a window that lasts 50 years and a window that lasts 10.

In this article, we’ll talk about what the IGU is, how it’s made, what makes it so important, and what you need to know to evaluate the IGU of any window or door.

What is an Insulated Glass Unit (IGU)?

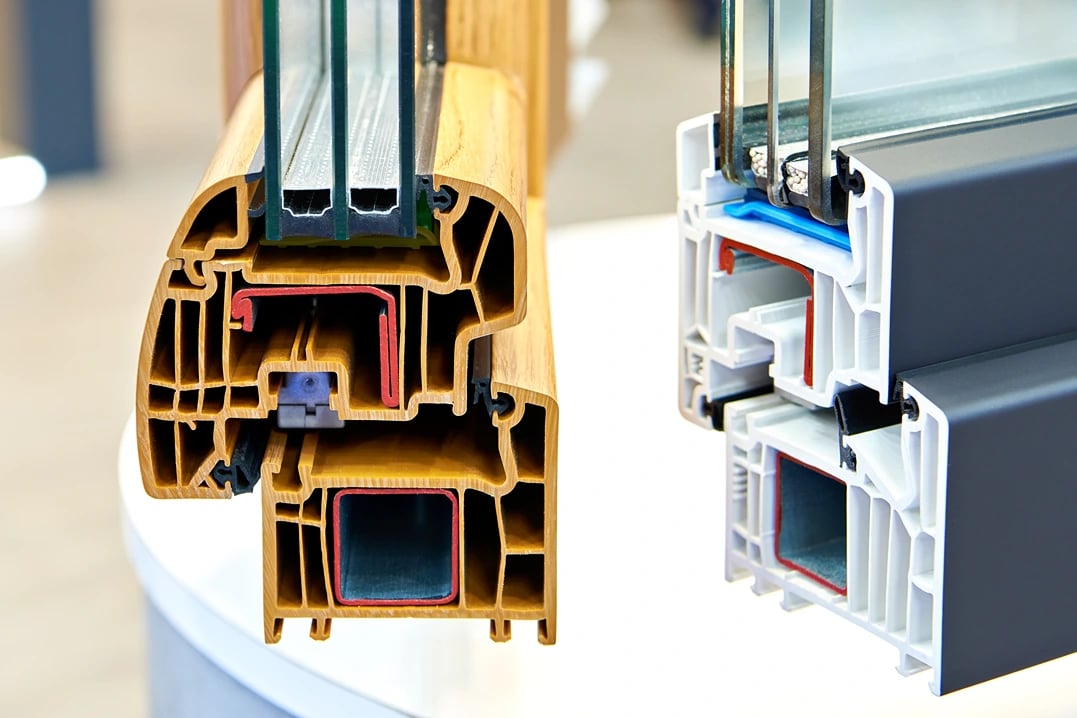

An Insulated Glass Unit (IGU) is an assembly composed of two or three panes that are separated by a spacer and sealed around the edges to create a hermetically sealed air or gas-filled space between the panes.

A well-made IGU reduces heat transfer and noise penetration and prevents condensation between the panes.

Components of an IGU

An IGU has five main components: the glass panes, the spacer, the desiccant, the gas fill, and the sealant.

Glass Panes: The number of glass panes in an IGU typically ranges from two to three. These panes are often treated with coatings (like low E coatings or tints) to improve thermal and optical performance.

Spacer: The spacer separates the glass panes and is filled with desiccant to absorb moisture.

Desiccant: Integrated into the spacer, the desiccant absorbs any infiltrating moisture to prevent fogging or condensation.

Gas Fill: The space between the glass panes is often filled with inert (and perfectly safe) gases like argon, krypton, or xenon, which have lower thermal conductivity than air, insulating the window. Filling a window with argon gas (as opposed to air) can improve a window’s U-value (insulation performance) by up to 16%.

Sealant: A sealant is applied around the edges of the assembled panes and spacer. The primary sealant provides the initial adhesion and hermetic seal, while a secondary sealant adds structural support and durability.

Why are IGUs Important?

Windows and glass doors may seem like fairly simple products, and, compared to a SpaceX rocket, that's true. But modern windows are a far cry from the simple single-paned windows of the past. They’re complex works of structural engineering, designed to be highly energy efficient, block specific wavelengths of light, and last for up to 50 years.

This means that quality can vary between different designs and manufacturers.

The glass panes themselves may perform well, but if the sealants fail, or the spacer isn’t energy efficient, then your windows or doors could fail much faster (in just three or four years in some cases), driving up your energy bills and allowing mold-growing condensation to infiltrate between the glass panes.

Energy Efficiency

The primary benefit of IGUs is their ability to improve the energy efficiency of a home. By reducing heat transfer, IGUs help maintain consistent indoor temperatures, potentially saving you thousands of dollars per year in heating and cooling.

Sound Insulation

IGUs can also reduce noise pollution. The combination of multiple layers of glass and the gas-filled space acts as a sound barrier, keeping street noise out.

Condensation

The hermetically sealed environment of an IGU, along with the use of desiccants, minimizes the risk of condensation forming between the panes, which can lead to mold growth and structural damage over time.

Longevity

Once the IGU fails, it’s only a matter of time before you need to replace your window or door, as energy efficiency plummets and mold-causing moisture begins to develop.

Evaluating Different Brands and Products with IGUs

So how do you evaluate IGUs? How do you know which brands will stand the test of time?

There are a few key considerations:

1. Glass Type and Coatings

Low-E Coatings: These coatings are applied to glass surfaces to reduce the amount of ultraviolet and infrared light that can pass through the glass without blocking visible light.

Understanding the type of low e coating in your window is important because different types are suitable for different climates and purposes.

Tinted Glass: Depending on your climate and the direction your windows face, you might consider tinted glass, which reduces glare and solar heat gain.

2. Gas Fill

Types of Gas: While Argon is the most popular option for gas fill because it is both effective and affordable, krypton and xenon can achieve the same level of insulation in a smaller space. For this reason, krypton and xenon are more common in triple-paned windows.

While krypton and xenon have slightly better thermal performance, they are also more expensive, and in many cases won’t net you enough energy savings to be worth the additional price.

3. Spacer Material

Thermal Performance: While most people focus on the gas fill or the frame, the spacer material is also an important part of the IGU’s insulation performance. Aluminum is the most commonly used spacer material, but, while it has excellent structural properties, it’s a very good heat conductor and typically reduces the window’s energy efficiency.

For this reason, “warm-edge” spacers were introduced. Most warm edge spacers are made from a durable plastic composite that performs well both structurally and thermally.

5. Comparing Manufacturers

While there are many different window and door companies, like Pella, Anderson, Anlin, Marvin, and others, most of these companies get their IGUs from just two major glass suppliers, Cardinal Glass and Guardian Glass.

At Southwest Exteriors, we strongly recommend windows and doors that use Cardinal Glass IGUs. Their rate of seal failure is one of the lowest in the industry, at just 0.47% over a window or door lifespan of 50 years. By contrast, the average seal failure rate among all other IGUs is 8% over a 20-year window or door lifespan. And for lower-end IGU manufacturers, the rate of seal failure can go as high as 15% over a 20-year window or door lifespan.

An important note: Some companies that advertise their use of Cardinal Glass may only be using Cardinal's glass panes, not their IGUs. This is an important distinction because seal failure, not glass failure, is the most common cause of IGU problems.

6. Energy Ratings and Certifications

Energy Star Certification

Energy Star is a widely recognized certification for energy efficiency. Products with the Energy Star label meet strict energy performance standards set by the U.S. Environmental Protection Agency (EPA).

For IGUs, this means they have been evaluated for their ability to retain indoor temperatures, reduce energy consumption, and ultimately lower utility bills.

NFRC Labels

The National Fenestration Rating Council (NFRC) has a comprehensive rating system that allows you to compare the energy efficiency of different window products. The NFRC label includes several key performance ratings:

U-factor: Measures how well a window can prevent heat from escaping. The lower the U-factor, the better the window insulates.

Solar Heat Gain Coefficient (SHGC): Indicates the fraction of solar radiation admitted through the window. A lower SHGC means less solar heat is transmitted, which is particularly beneficial in warmer climates to reduce cooling needs.

Visible Light Transmittance (VLT): Measures how much light passes through a window. Higher values indicate more natural light, which can reduce the need for artificial lighting.

Learn all about window ratings in our article, How To Interpret Window Ratings.

Full Window/Door Replacement or Glass-Only Replacement?

If you're looking to replace your windows? If so, should you replace just the glass or the entire window? We answer this question in-depth in our article, Full window replacement vs. Glass-only replacement: Which is right for you?